The BEV systems can be used in small passenger vehicles where the daily mileage

limit is quite low. Concerning trucks, the use of FCEVs starts to be very beneficial. Fuel

cells require far fewer raw materials in the production stage than electrochemical batteries.

An additional advantage is the lack of cobalt and the limited use of platinum

(compared to internal combustion engine vehicles).

The current price of hydrogen for end-user transport in Europe ranges from EUR 5

to EUR 9.5 per kg, depending on the region. The lowest price is because it is

produced as a waste product in industrial chemical processes, while the highest price is

a contractual price intended to equate the cost of operating a fuel cell car with a spark

ignition (SI) engine.

According to the Hydrogen Council [3], the price of hydrogen for fuel cells will

decrease by about 60% for the end user over the next decade. This will occur in regions

with access to cheap natural gas and the ability to store captured CO2. In addition, with

an increased demand for hydrogen, the cost of hydrogen supply over the coming decade could

|

| Figure 2. Comparison of refueling performance and investment rates for traditional and near-future fuels . |

decrease by as much as 70%. As a result, the cost of distributed hydrogen in 2030

could be in the range of USD 4.5–6 per kg. A comparative analysis of refueling vehicles

with conventional fuels, hydrogen, and recharging batteries at the filling station shows

(Figure 2) that this time is significantly shorter for conventional fuels and hydrogen than

electric vehicles, while hydrogen provides a much greater driving range than in the case of

electric vehicles. Additional factors favoring hydrogen as a fuel are the investment costs

associated with the construction and size of refueling stations

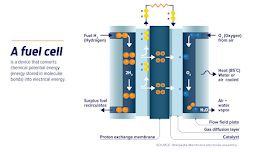

2. Analysis of Hydrogen Usage in Internal Combustion Engines and Fuel Cells

According to the Hydrogen Council, the CO2 emission of hydrogen pathways (the

well-to-tank stage) from natural gas via SMR (steam methane reforming) was ~75 g/km,

accounting for ~60% of the total CO2 emissions of an FCEV from a lifecycle perspective [4].

Most hydrogen today is produced from fossil fuels and emits carbon (grey hydrogen). For

producing low-carbon hydrogen from natural gas with CCS, the following two technology

options exist steam methane reforming (SMR) and auto thermal reforming (ATR) [3]. SMR

combines natural gas and pressurized steam to produce syngas, a blend of carbon

monoxide and hydrogen. ATR combines oxygen and natural gas to produce syngas. This

process can easily capture up to 95% of CO2 emissions. ATR technology is typically used

for larger plants compared with SMR technology. Based on the data presented in [5],

CO2 emission during hydrogen production is (kg CO2−e/kg H2): coal gasification (no

CCS)—12.7–16.8; coal gasification and CCS (best case)—0.71; SMR (no CCS)—8.5; SMR

and CCS (best case)—0.76.

The data compiled by the International Council on Clean Transportation Europe [6]

show that the average real-world fuel (kg) and electricity consumption (kWh/100 km)

values for lower medium and SUV segment cars registered in the European Union are,

respectively, BEV: 20.6 and 21.9 kWh and FCEV: 1.0 and 1.2 kg.

In a study, the authors of [6] stated that the life cycle for GHG emissions of average

gasoline- and diesel-powered ICEVs (internal combustion engine vehicles) are very similar

and range from 226–227 g CO2 eq./km for small, 245–246 g CO2 eq./km for lower medium

and 266–288 g CO2 eq./km for SUV segment cars. The emissions from FCEV vehicles

look similar to the following: of the medium segment, 202 g CO2 eq./km (from natural

gas) and 55–60 g CO2 eq./km (from renewable hydrogen). However, the data presented

in [7] show that in some European countries, the amounts of the average carbon footprint

over a lifetime (segment D) are significantly different: Germany—426 g CO2 eq./km and

France—112 g CO2 eq./km. This is mainly due to how hydrogen is produced

3. Materials and Methods

3.1. Research Objects

The research was conducted using a Toyota Mirai first-generation vehicle (Table 1).

The vehicle uses components from Toyota’s hybrid vehicle models mass-produced since 1997. These components consisted of the vehicle’s power management unit, known as the power controller and the voltage converter, both used from a third-generation Prius model; the traction electric motor was taken from a Lexus RX 450h hybrid model; and the high-voltage battery was taken from a Toyota Camry model.

Figure 3. Toyota Mirai hydrogen system component layout (based on [33]).

The generation of the fuel cell used in this model has a volumetric energy density

28 times higher than that of the first generation used by Toyota. The first generation had a

volumetric energy density of only 0.11 kW/dm3, while the one used in the tested Mirai

model is 3.1 kW/dm3. This was achieved, partly due to the design of the cell stack with

a configuration that allows internal self-humidification, using the circulation of water

produced in each cell. This feature eliminated the need for a humidifier, significantly

reducing the volume of the entire cell stack.The vehicle has two tanks of 120 and 122 dm3, holding a total of 5 kg of hydrogen (Table 2). The calculated ratio of the mass of hydrogen, at maximum hydrogen filling, to the empty mass of the tanks is 5.7%.

|

| Figure 4. Course of the RDC test with characteristics phases |

4. Results

4.1. Driving Test Evaluation

The main problem of a constantly developing industry is its negative impact on

the environment. Transportation is one of the most rapidly changing industries, and it significantly affects the concentration of hazardous substances in the air. To reduce the impact of vehicles on the environment, increasingly stringent standards for exhaust emissions are being introduced and solutions are being developed to minimize vehicle emissions. Exhaust emission standards are set to control the pollutants emitted from automotive vehicles around the world. Exhaust emission values are measured under conditions in an established type of approval test. This part of the vehicle certification process is responsible for the environmental performance of the vehicle and is the same for all passenger cars. The course of the test corresponds to the most likely road conditions, and the tests performed, which are the same for all vehicles, authorize the comparison of emission results between them. Nowadays, the focus is more and more on road testing, i.e., testing under real driving conditions. These tests have now been integrated into European Union regulations under the name RDE (Real Driving Emissions) [37,38]. These are made to best reflect the actual operating conditions of the vehicle in terms of environmental aspects. The research presented in this paper omits the analysis of exhaust emissions (which, in a fuel cell vehicle, is zero), focusing on the analysis of the energy consumption of a modern propulsion system based on RDE test standards. With this in mind, the authors refer to this test by the acronym RDC (Real Driving Conditions) [39,40]. Due to increasing electrification of vehicles, comparative work on the energy consumption of propulsion is extremely important for the development of the transportation field. The RDC (RDE) test procedure is universal within the European Union and can be carried out on selected sections of a road that meet the basic requirements. The route is divided into three sections corresponding to the speed of urban, rural and motorway driving conditions. The test was performed with the FC vehicle in Warsaw (Poland) and met all the requirements, as shown in Figure 4.

|

Figure 4. The course of the RDC test with characteristics phases (S = 102.8 km, t = 114.5 min).

|

4.2. State of Charge (SOC) Change Analysis

The drive system of the Toyota Mirai is equipped with a high-voltage nickel-metal hydride battery. During driving, the battery is charged and discharged due to the charac- teristic parameters of the route, such as the amount of acceleration and braking in a given section of the route. The energy recovered during braking can be reused to power the vehicle, as is the case in hybrid and electric vehicles. The study identified the areas with

the highest and lowest average battery charge levels (Figure 5a).

|

Figure 7. Average and maximum changes in battery (discharge and regeneration) and fuel cell contributions during each phase of the RDC test.

|

Due to the individual driving parameters, some speed ranges recorded lower energy consumptions, however, the justification for these results should be found in the temporary driving conditions, for example, the lowest average energy values were obtained in the speed range 41–50 km/h, this speed usually occurs only in transition states between acceleration and deceleration to the maximum speed of the urban speed range. Over a wide range of speed ranges, similar energy recovery values were recorded for both the

urban and rural sections, indicating the versatility of energy recovery at varying speeds.

4.4. Evaluation of Electric Drive Operating Conditions and Energy Consumption

The energy to operate the vehicle comes mainly from the fuel cell, transient situations caused by acceleration additionally consume energy from the high-voltage battery, but in total, due to energy recovery to the battery during braking, the energy flow from this source becomes neutral. The small changes between EC_ALL and EC_FC are due to the inclusion of changes in battery discharge (EC_BATT) and battery recharge due to recovery

regenerative braking (EC_REC), according to the following equation:

EC_ALL = EC_FC

−EC_BATT+EC_REC (6)

In this way, the difference between EC_ALL and EC_FC is not significant because the

battery usage and recharge is close to zero. These conditions are illustrated in Figure 8.

|

Figure8. EnergyconsumptionconditionsintheRDCtestphases(ECU—energyconsump- tion in urban phase, ECR—energy consumption in rural phase, ECM—energy consumption in

motorway phase).

Confirmation of the above statement regarding the main use of the fuel cell for vehicle propulsion is provided by an analysis of the energy flow shares (discharge and charge) per vehicle speed for the battery (Figure 9). It can be concluded that in selected speed ranges, the regenerated energy is equal to the energy consumed during driving or acceleration. However, it should be remembered that this graph only shows the energy flow from the battery and the fuel cell is also used for propulsion, which generates much more energy to drive the vehicle. The drive characteristics also indicate that braking energy recuperation only occurs until 8 km/h, below which the vehicle decelerates using the conventional braking system. The highest energy consumption from the battery was recorded for accelerating the vehicle from a standstill when the fuel cell is not yet generating the required propulsion power. In the presented single RDC test, the total energy recovered is 322 Wh more than the energy consumed; therefore, the energy recovery system is highly efficient (the battery does not require an external source of charge to obtain the energy needed to drive the vehicle—part of the energy also comes from the operation of the fuel cell, what is indicated later in this article). |

|

Figure 9. Shares of battery energy use during discharge and charge in relation to driving speed. |

Complementing the presented summary evaluation of the powertrain during the RDC

test is a discussion of energy flow on selected instantaneous single vehicle acceleration and deceleration states. Based on Figure 10, it is possible to describe the following characteristic operating points of the drive system:

1. duringvehicleacceleration,theinitialenergyinputfromthebatteryisvisibleuntil

the fuel cell starts producing energy (for further analysis see Figure 11);

2. duringbraking,thefuelcelloperationisshutdownandtheenergyisrecoveredto

the high-voltage battery;

3. dependingonthevehicle’saccelerationrate,largeramountsofenergyareconsumed

from both the battery and the fuel cell sources;

4. whenthevehicleisstandingstill,theenergyrequirementsoftheon-boardsystems

(comfort, entertainment) are fulfilled by the high-voltage battery.

|

Figure 10. Interaction of powertrain components during driving of Toyota Mirai |

|

Figure 11. Analysis of a selected single acceleration process of a FC vehicle. Regardless of the energy source, the wheel propulsion is provided entirely by the electric motor. It is, therefore, important to recognize the operating conditions of the drivetrain (Figure 12). During the entire RDC test, the powertrain generates 83.7% of the vehicle’s propulsion and 16.3% of the energy is recovered during braking. During both propulsion and braking of the vehicle, the powertrain operates within the voltage range of mainly 300–350 V—achieving more than 60% of the total time share. Individual operating points generate higher voltages in the range of 350–652 V; however, the total share of these values is much lower (these are noted at intervals of higher vehicle speeds or higher powertrain loads). The maximum torque achieved during the test was 216 Nm, which is 65% of the max torque claimed by the manufacturer; therefore, the drivetrain in the RDC test does not require maximum torque to complete the run. The regenerative braking characteristics indicate a constant braking torque in the electric motor speed range 1500–9000 rpm at the level of 15 Nm. Regenerative braking is only possible down to a speed of about 7 km/h. |

|

Figure 12. Characteristics of an electric motor in relation to its operating voltage. |

The charging and discharging conditions of the high-voltage battery are shown in Figure 13. Although the nominal voltage is reported as 244.8 V, its operating conditions indicate much larger positive fluctuations around this value. The minimum value fluctuates around 240 V, but the maximum value far exceeds 300 V. The operating conditions of the battery indicate that it is possible to receive about 26 kW of power when discharged. During its charging, much higher power values were obtained (more than 32 kW), indicating slightly different charging and discharging conditions (with similar current values); the

voltage variations are around 20 V.

|

| Figure 13. Characteristics of a high voltage battery. |

The version of the first-generation Toyota Mirai powertrain presented in this paper includes a Fuel Cell Boost Converter. This is a significant change from the powertrain presented in 2008 (designated as Toyota FCHV adv). This means that the fuel cell using boost can largely self-power the vehicle’s electric motor. The operating conditions in Figure 14 indicate that at a fuel cell current value of about 100 A, the converter maintains a voltage of 650 V. For current values from about 200 A, the converter converts voltage from the cell to the maximum level of 650 V. The voltage–current characteristics of the fuel cell indicate voltage values of 200–300 V at no load to about 200 V at maximum current values of over 350 A. The power characteristics of the fuel cell do not have a typical maximum; therefore, increasing the current increases its power. Thus, applying voltage amplification at a specific current value, in this case at about 100 A, effectively increases the power

directed to the electric motor.

|

| Figure 14.Current–voltage characteristics of a fuel cell and its voltage converter. |

An evaluation of the total energy flow in the Toyota Mirai drive system is shown in Figure 15. The contribution of the HV battery in the individual phases of the RDC test is not large—as the driving speed increases, the contribution decreases. For the entire test, the share of battery utilization is about 13%. The share of energy recovery to the battery (regenerative braking and fuel cell charging) is slightly higher. The larger values of energy recovered to the battery apply to each phase of the test—approximately 0.6 percentage points on average. This shows that in the entire driving test, slightly more energy was supplied to the battery than was used. Energy flow analysis shows the vehicle consumed 22.285 kWh in the test. However, the fuel cell “produced” 22.60 kWh, which is indicated in Figure 15—as 101.5% of the total energy consumed. This difference is due to the energy recovery to the battery. Summarizing the energy flow in the RDC test, it should be stated that the contribution of the fuel cell to the vehicle’s propulsion is more than 70%. The rest

is half, indicating the battery’s contribution and energy recuperation.

|

| Figure 15. Energy consumption conditions for the RDC test phases and the entire RDC test. |

5. Conclusions

Modern hybrid drives that use a fuel cell instead of an internal combustion engine as

the main source of propulsion are now a trend in the development of future zero-emission automobiles. The advantage of fueling the vehicle quickly is a key advantage over electric vehicles, which take much more time to charge depending on the charging type. Fuel cells are a multipurpose source of electricity that can be converted to electric drive in basically any type of propulsion system; therefore, the research presented above is important because of the recognition of the energy balance of such vehicles. The widespread use of fuel cells in automobiles, trucks and even maritime transport brings significant benefits. However, the global use of this type of propulsion depends on the development of a hydrogen refueling infrastructure. The study determined at what ranges the drive is realized with a fuel cell, and in what ranges a high-voltage battery is engaged. The operating conditions of these systems have been specified.

The above analysis of the operating conditions of the hydrogen vehicle propulsion system under real traffic conditions (according to the RDE test procedure) indicates the

following:

• In most cases,thehighvoltagebatteryischargedonlyfromenergyregeneration

during braking; however, there are also situations where the battery is charged from

the energy generated by the fuel cell (in the test, the battery charge from the fuel cell

reached 0.315 kWh—Figure 15);

• As the vehicle speed increases (inotherwordsastheRDCtestintervalchanges), the

battery energy consumption decreases and the fuel cell energy consumption increases

(Figure 15);

• The vehicle is initially started from standstill by using a high-voltage battery, only after

a certain time, depending on the load is the fuel cell activated (Figure 11).

0 Comments